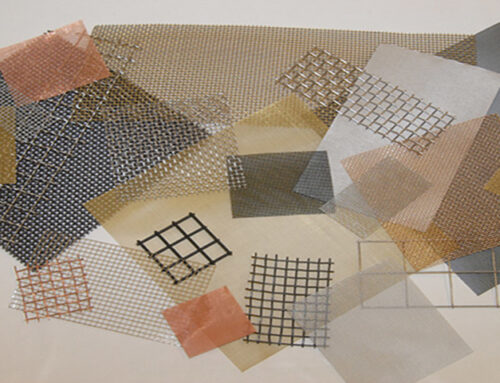

Each industry has its own specific terminology – and the wire cloth industry is no different. Below are the most common terms used when discussing wire, wire mesh and cloth, and the different types of weaves and manufacturing methods.

Wire Cloth Terms

Acoustic Mesh

This mesh is woven to achieve specific sound attenuation objectives typically defined by a precise Rayl value and measured with precision instrumentation. Most often, an acoustic mesh is manufactured using micron-rated weaves.

Broad Mesh Twilled Weave

To optimize the filtration capacity of the cloth, the shute wires of the broad mesh twilled weave are arranged loosely instead of being close to each other. This means that the retention accuracy is lower than that of a classic twilled weave. Nevertheless, the accuracy is sufficient for the requirements of most applications. In addition, this modified weave allows significantly higher flow rates with low loss of pressure and good regeneration characteristics. The surface of the BMT cloth is smooth on both sides, meaning that the filter can be easily cleaned.

Calendered Wire Cloth

Wire cloth that has passed through a pair of heavy rolls to reduce the thickness of the fabric, or to flatten the intersections to provide a smooth surface.

Clear Opening (Space, Open Area)

Space between adjacent parallel wires. Often relayed as a percentage.

Crimp

Corrugations in wires permit locking them in place when perpendicular to one another.

Double Crimp

This option crimps down on both the warp and shute wires, creating a winged look.

Double Intermediate Crimp

Usually, the warp wires lay in every crimp in the shute wires, and the shute wires lay in every other crimp in the warp wires.

Easy Clean Wire Cloth

A plain mesh that can be woven in either Dutch or Reverse Dutch and provides high flow rates and excellent backflushing properties.

Fill Wires (Shute Wires)

Wires running across the width of the cloth as a woven

Gauge (Wire Size)

To avoid possible errors, specify wire diameter in decimal sizes rather than gauge numbers.

Intermediate Crimp

Warp and shute wires lay in every other crimp.

Market Grade

The most commonly used sizes of industrial wire cloth and the best balance of the combination of mesh count and wire diameter that create the most uniform weave.

Mesh

The number of wires from the center of one wire to a point 1” distant.

Mesh Count

The number of wires from the center of one wire to a point 1” distant.

Mill Grade

A wire mesh grade in between Market Grade and Tensile Bolting Cloth with slightly more open air. This type is typically used in separation.

Plain Weave

The plain weave has its origins in braiding. With this weave, the material is interwoven. Each warp wire and each shute wire pass over one and under the next adjacent wire. Wires are crimped in the weaving operation. There are a number of ways of doing this, making the family of plain weaves extremely diverse with respect to appearance and structure.

Plain Dutch Weave

Like plain weave, the wire in plain dutch weave is interwoven but the warp wires are thicker than the shute wires. These are arranged very close together to form a zero-mesh structure. This generates a weave that has high inherent stability with a relatively small mesh size. Plain dutch weave has excellent filtration qualities and can be easily cleaned of filtrate deposits and residual dirt.

Plain Dutch Weave HF (High Flow)

This cloth, which is woven in the same way as the classic plain dutch weave, earns the title “High Flow“ through the high flow rates that it allows. These are due to the shute wires being considerably thinner than usual which doubles the pore count. As a result, this cloth has a much higher contaminant trapping capability. With a free open area of 28 – 42%, the HF performs better than other filters with a similar mesh count.

Permeability

The ability of a wire mesh to allow gas or liquid to pass through it. Air permeability is defined as the rate of airflow passing through a known area under prescribed air pressure.

Porosity

Wire mesh porosity is defined as the volume of the mesh pores/openings in relation to the total volume of the wire cloth expressed as a percentage.

Rectangular Openings

The long dimension of an opening can be specified as parallel or perpendicular to the length

Reverse Plain Dutch Weave

“Reverse” describes the fact that the warp wires of this weave are relatively thin and the shute wires are thick – in other words, the exact opposite of the standard dutch weaves. The reverse dutch design produces precisely defined pore openings that run under an angle to the surface of the mesh. The high number of warp wires increases the active filtration cross-section. Depending on the specifications, this can be approx. 21 – 25%. The reverse dutch weave is available in “heavy” and “light” versions. The light version has a special wire combination that increases the active filtration cross-section to 25 – 38%.

Reverse Dutch Twilled Weave

An important version of the reverse dutch weave is the reverse dutch twilled weave. With this weave, the warp wires are also relatively thin – as in the case of the normal reverse dutch weave. The difference is the twilled weave pattern of the shute wires. This means that the warp wires are not as heavily deformed and physically stressed as in the case of plain weaves. The strength of this weave design is its suitability for applications that are subject to high levels of mechanical stress.

Selvage

Finished edges running the length of the roll to prevent unraveling.

Shute Wires

Wires running across the width of the cloth as woven.

Slotted Opening

Weave in which shute wires are arranged to provide rectangular openings.

Space Cloth

When a mesh is defined by the clear opening (space) instead of the mesh count. Usually associated with pre-crimped weaves or when the opening is large (1/2”, 3/4” or 1” opening, for example).

Square Mesh

Wire cloth with a mesh count the same in both directions. Plain Square Mesh is the most common weave with the same number and diameter of warp and shute wires woven in a simple over and under pattern. Creates maximum weaving stability and the same mesh count in both directions.

Tensile Bolting Cloth

This mesh provides greater open-air % for the same mesh count by using thin wires. Very commonly used in separation.

Twilled Weave

In a twill weave, each warp wire and each shute wire pass successively over two and under the next adjacent pair of wires.

Twilled Dutch Weave

As with the plain weave, the shute wires of the twilled dutch weave (TDW) are arranged as close together as possible. However, this weave has double the number of shute wires as a plain dutch weave. A very small aperture is formed by three shute wires which cross in different directions and, together with the warp wires, create a channel that is open on two sides. The characteristic structure of this tight weave provides high filtration accuracy. Another variation of this is Open Twilled Dutch Weave where fewer shute wires are used to influence the filtration rate.

Warp Wire

Wires running the length of the cloth as woven.

Weave

Refers to the type of interwoven warp and shute wire pattern found within the mesh. There are various sorts of weaves used for different types and applications.

Weft Wires

Another name for Shute Wires, i.e., those running across the width of the cloth.

Welded Wire Cloth

Warp and shute wires lay flat (no crimp ), welded at the intersections.

VarLL’s Expertise

While the above glossary does not cover every wire cloth/mesh term in the industry, it includes the majority of terms our experienced engineers and weavers use. If there is a term we left out, we would love to hear from you!