Wire Mesh and Cloth Weaving

To meet customer demand for specialized mesh and localized manufacturing, we weave technically advanced weaves such as sound modulation acoustic mesh and high-value alloys in North American and European locations.

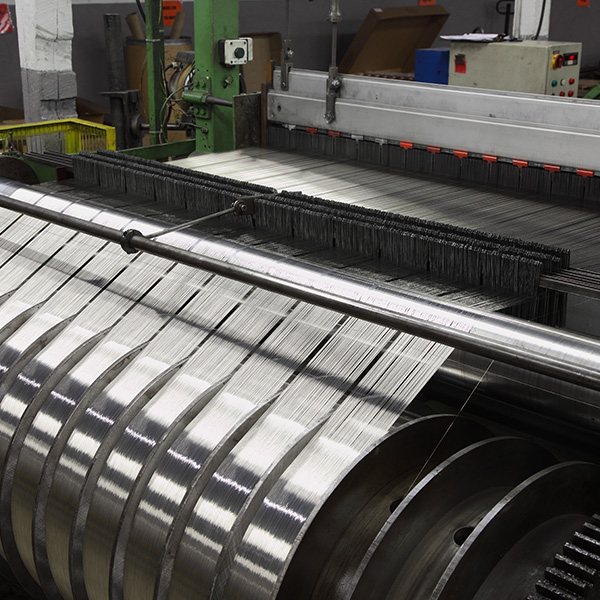

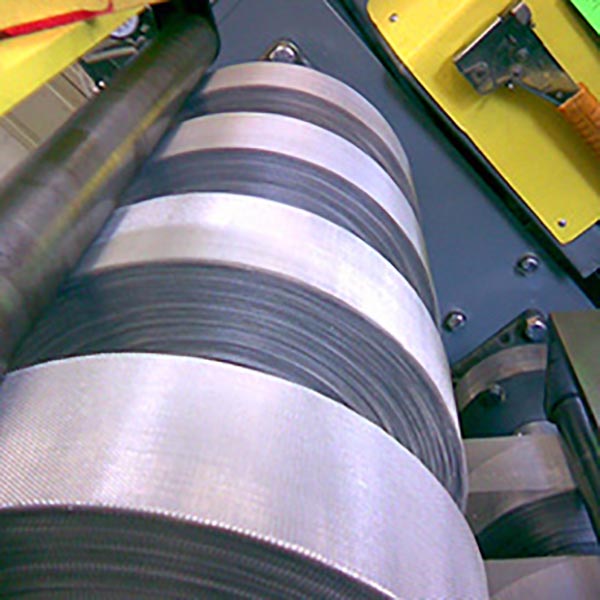

Slitting & Shearing

We offer slitting and shearing services to deliver a perfectly cut roll or piece part to your production line, allowing you to purchase only the wire cloth that you need and have it ready for production.

Coating & Finishes

We offer premium coatings and finishes that can enhance corrosion protection, durability, aesthetic value and electrical properties of the mesh, as well as numerous other benefits.

- Common metallic coatings (plating) applied to wire include nickel, copper, cadmium, zinc or tin.

- Non-metallic coatings include epoxy, polyester, Teflon, powder coat, galvanized and hydrophobic materials.

- Chemical processing can provide electro-polished, anodized, passivated, or etched finishes to the surface of the material.

Cleaning

Many customers require us to remove oils, dirt, or debris from their wire, wire cloth or wire cloth components. We offer a wide variety of cleaning methods such as vapor degreasing, ultrasonic, aqueous or thermal cleaning.

Calendering

Calendering flattens the wire and reduces the thickness providing a uniform and precise material thickness throughout the mesh. This is used for applications where a controlled thickness is necessary. This process also increases the stability of the woven wire cloth.

Heat Treatment

We offer batch and strip/strand heat-treating using either vacuum or reducing atmospheres for the following processes:

Welding

We have extensive capabilities to assemble smaller filtration and separation components using automated spot, seam and circumferential resistance welding processes. Larger filters, housing and other components are manufactured using TIG, MIG and Laser welding capabilities. Our processes are designed to ensure strong, quality welds while focusing on precision and repeatability.

Laser Cutting

Our laser cutter provides us additional capabilities to cut precise parts for filtration components. In addition, it allows us to process small runs and prototypes where a blanking machine is cost prohibitive.